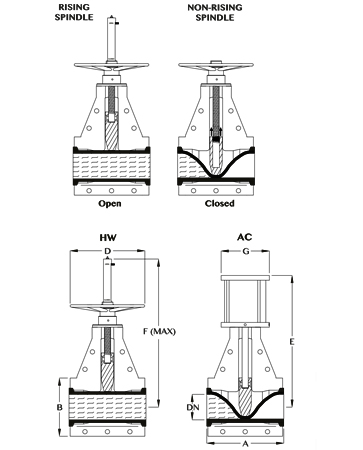

Dual Straight Through Pinch Valve (DSTPV)

DUAL‘s Straight-Through Pinch Valve consists of a tough, but flexible full bore sleeve, which forms part of the pipeline. The valve is closed mechanically via movement of a pinch gate located above the sleeve. The core of the Dual Straight-Through Pinch Valve is the sleeve. The valves are well suited for on/off and throttling control applications involving slurries, powders, liquids, granulated materials and applications where scale build is a problem.

FEATURES

The Dual Pinch Valves double-ended enclosed body with easily replaceable, flexible rubber sleeves

• Thrust bearing for ease of opening and closing (handwheel type)

• Long operating life

• Full bore, low friction loss

• 100% drip tight closure even with solids in the medium

• Light weight

• Seals in both directions

• High flexibility sleeve design reduces closing forces, improves recovery to full open position

• Enclosed body protects the sleeve from the environment

• Fast and easy sleeve change

• Single wearing part

• Face to face compatible with diaphragm valves

• No glands which require regular adjustment

• Rising and non rising spindle types

• Positive opening tags

• Open/closed sight glass indicator